New Scape Bin-Picker Feature: How to ensure high bin empty rates

March 16th, 2022

How to ensure high bin empty rates with SCAPE Bin-Picker Solution for robotic automated material handling

A wide range of industries and factory automation companies are having components or parts for products delivered in bins/boxes and every day, production workers spend significant time moving parts between boxes/bins and manufacturing machines. The manual material handling process has Scape Technologies solved via reliable, robust Robotic SCAPE Bin-Picker Solutions which increase productivity and reduce manual repetitive and monotone tasks, detrimental to the workers' health.

When looking closely at automated material handling with Robotic Bin-Picking it requires software expecting the unexpected. Scape Technologies’ solutions have several backup procedures that allow the system to continue picking parts also when unexpected events happen. Even if the robot encounters a challenge in the bin, the smart software solves the problem and allows for continued stable picking of parts that typically are positioned in a structured, semi-structured or random way in the bin. Each type of shape and positioning of the parts has its own complexity and characteristics and must be treated in accordance with these variables to empty the bin effectively.

Some parts have little or almost no 3D shape. The less 3D shape they have, the harder it can be to recognize them correctly in a 3D point cloud when using just the surface shape for the matching.

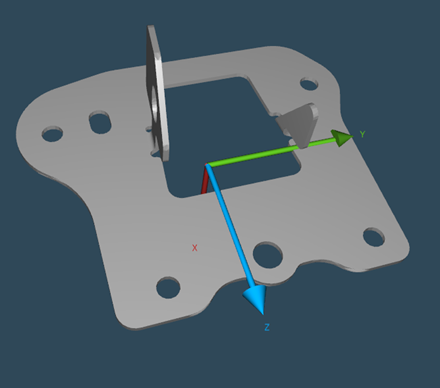

One example would be a part like this:

In order to ensure high bin empty rates with SCAPE Bin-Picker Solution for robotic automated material handling, we have taken the challenge to improve the recognition of parts with almost no 3D shape without compromising reliability and robustness in the SCAPE Bin-Picker Solution.

Challenge:

Ensure high bin empty rates with parts almost not having any 3D shape

Some parts have little or almost no 3D shape. The less 3D shape they have, the harder it can be to recognize them correctly in a 3D point cloud when using just the surface shape for the matching.

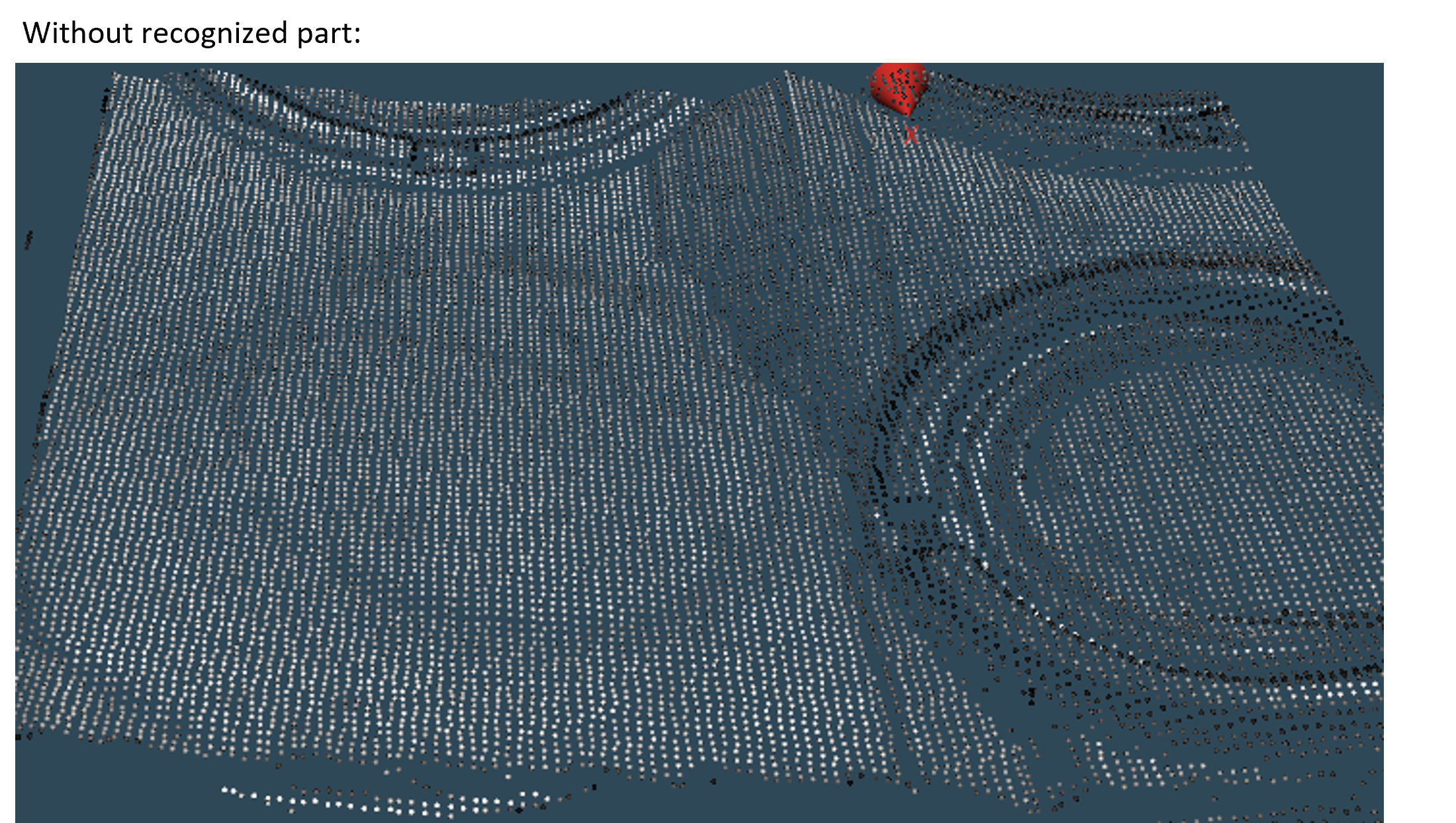

One example would be a part like this:

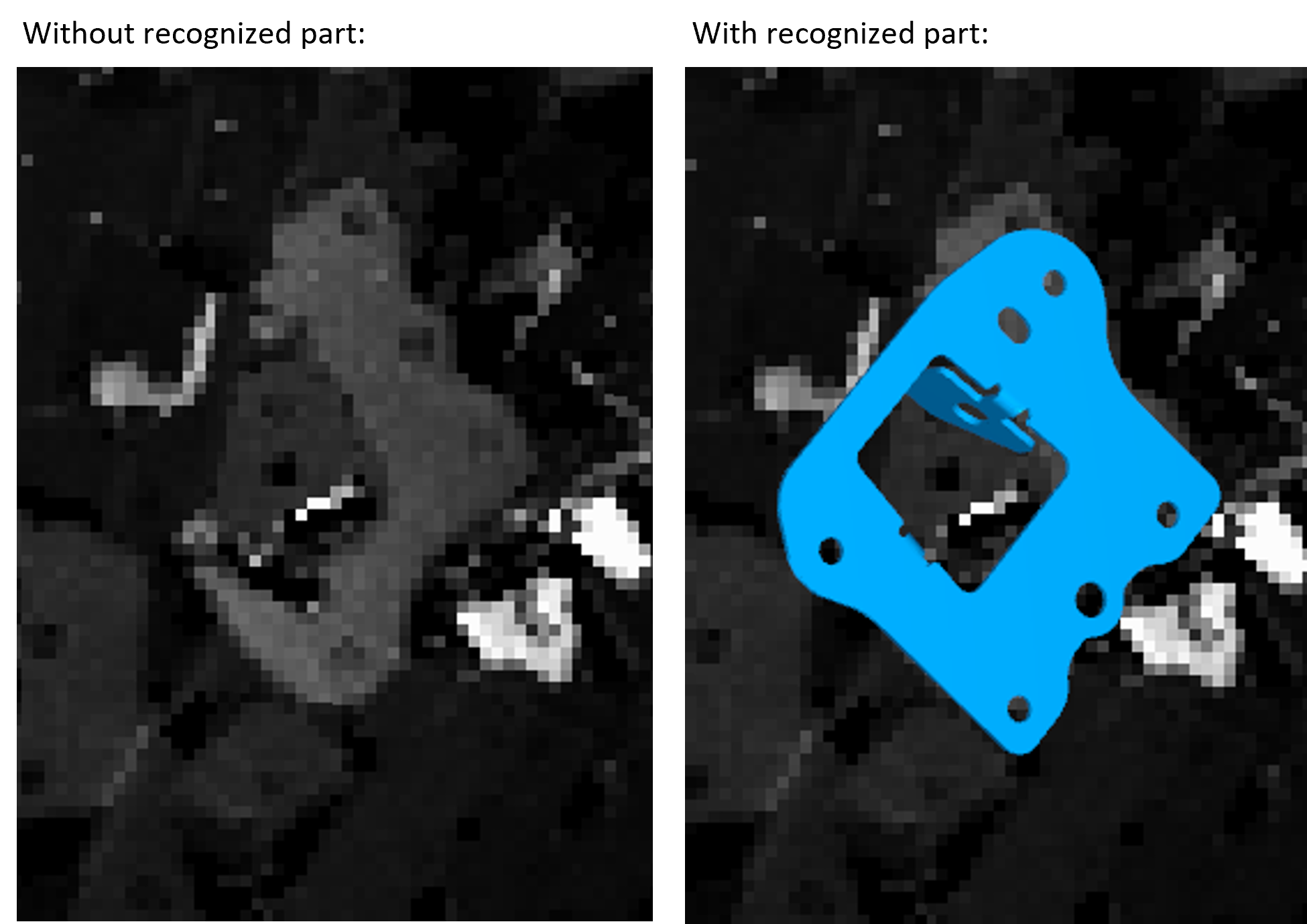

When just matching the surface of the part with the scanned point cloud, recognitions like this one might sometimes be seen:

The part is partly overlapped by another part on the left side and in the end, the best match is one where the general surfaces of the part match the scanned data. But the part has not been recognized in its actual pose.

Solution:

Use 3D Edges of parts for recognition

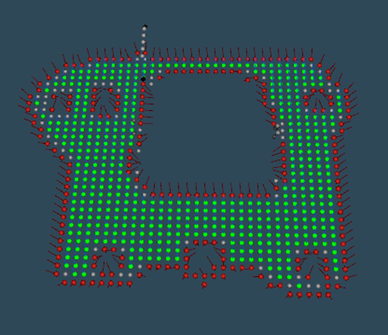

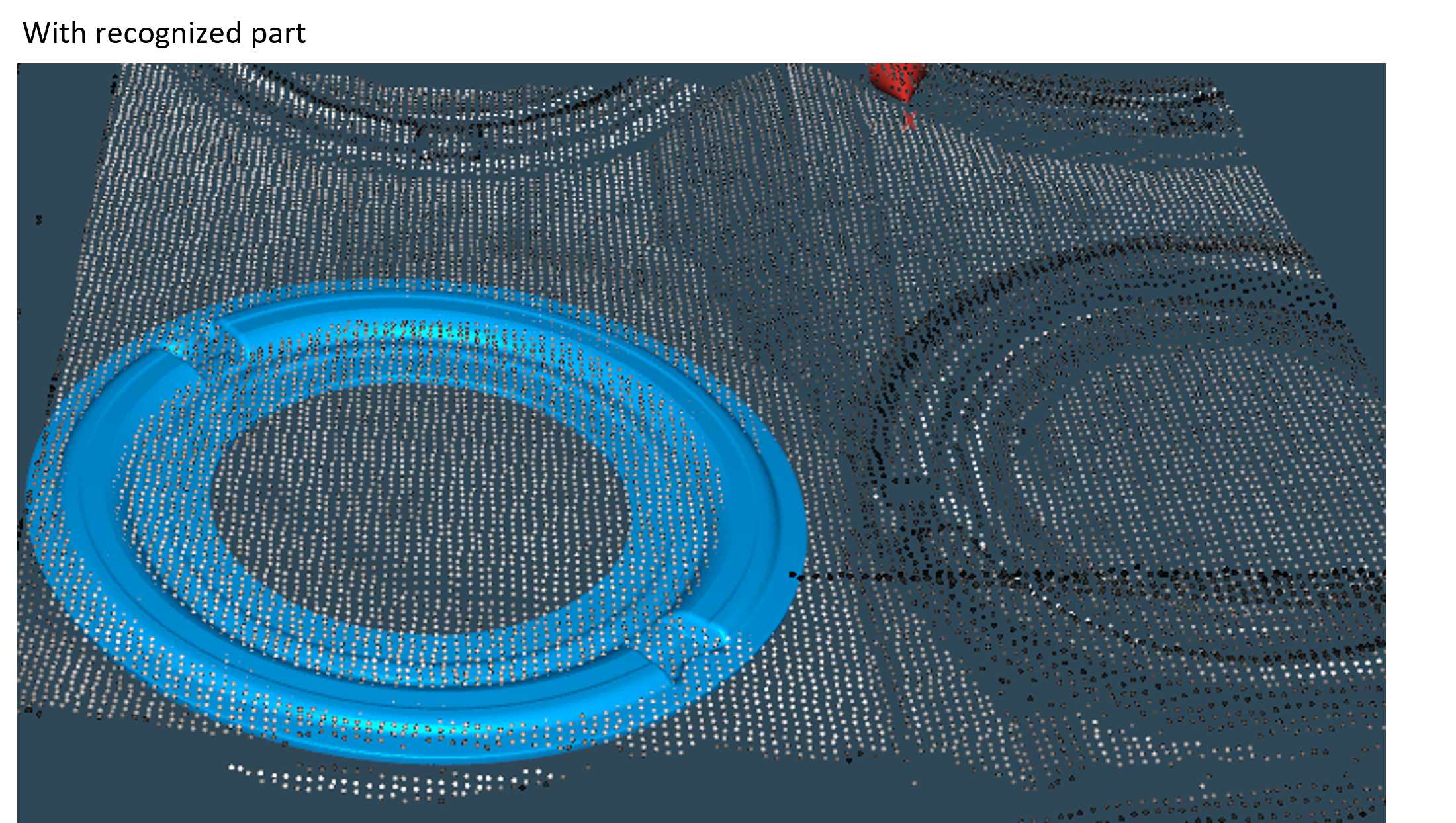

In order to improve this, we are now using 3D Edges of the parts for the recognitions. From the CAD model, the expected 3D Edges are extracted:

And these are then compared with the 3D Edges of the scan as part of the recognition.

The result:

Use 3D Edges of parts for recognition

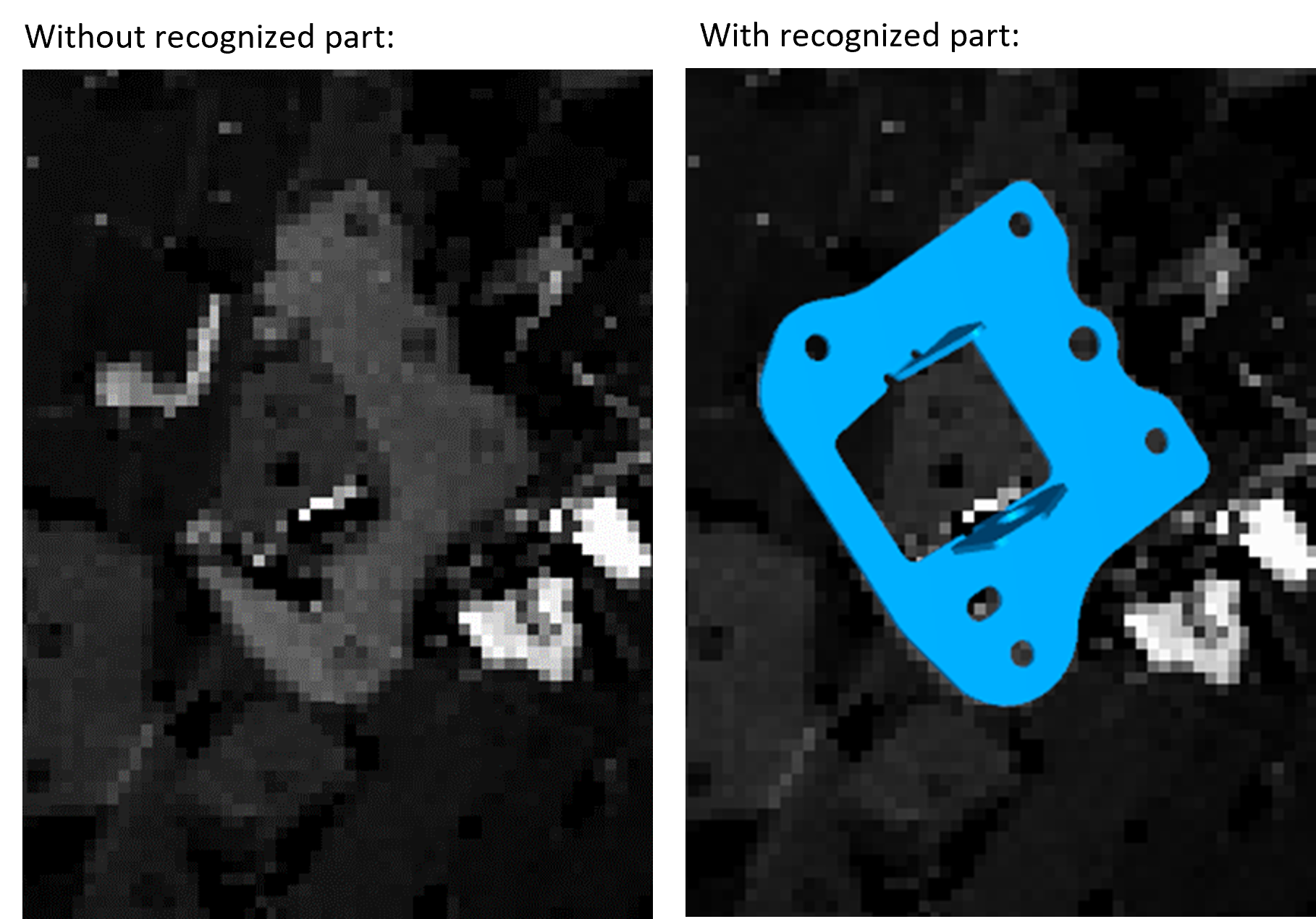

The previous part is now correctly recognized because this was how the 3D Edges would match the scan optimally:

Bonus:

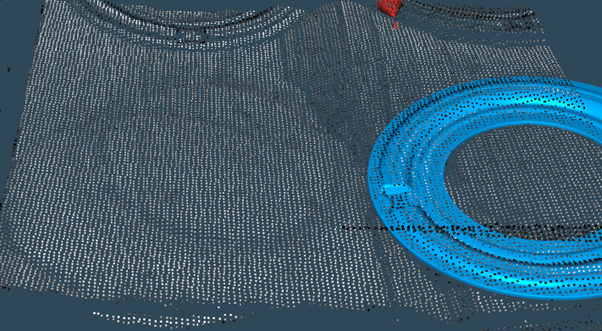

3D Edges have the additional advantage that they prevent false recognitions of parts on an almost flat background, e.g. a piece of cardboard: if a part has previously been lying on the cardboard, its shape can match the shape of the part extremely well.

But after introducing 3D Edges, wrong recognitions like these will no longer be present as the cardboard will not generate enough 3D Edges for a false recognition to be wrongly accepted as a correct recognition. Instead, only the part on the right is now recognized:

Conclusion:

Ensure high bin empty rates with parts almost not having any 3D shape

By using 3D Edges, the overall performance of the SCAPE Bin-Picking System has been greatly increased, as parts can now be recognized in the correct position and orientation more reliably. Especially flat parts can now be picked much more accurately, reducing the number of failed grips in the bin and leads to shorter average cycle times. Furthermore, the new features ensure high bin-empty rates without compromising the stability and safety of the system, leading to shorter changeover times.