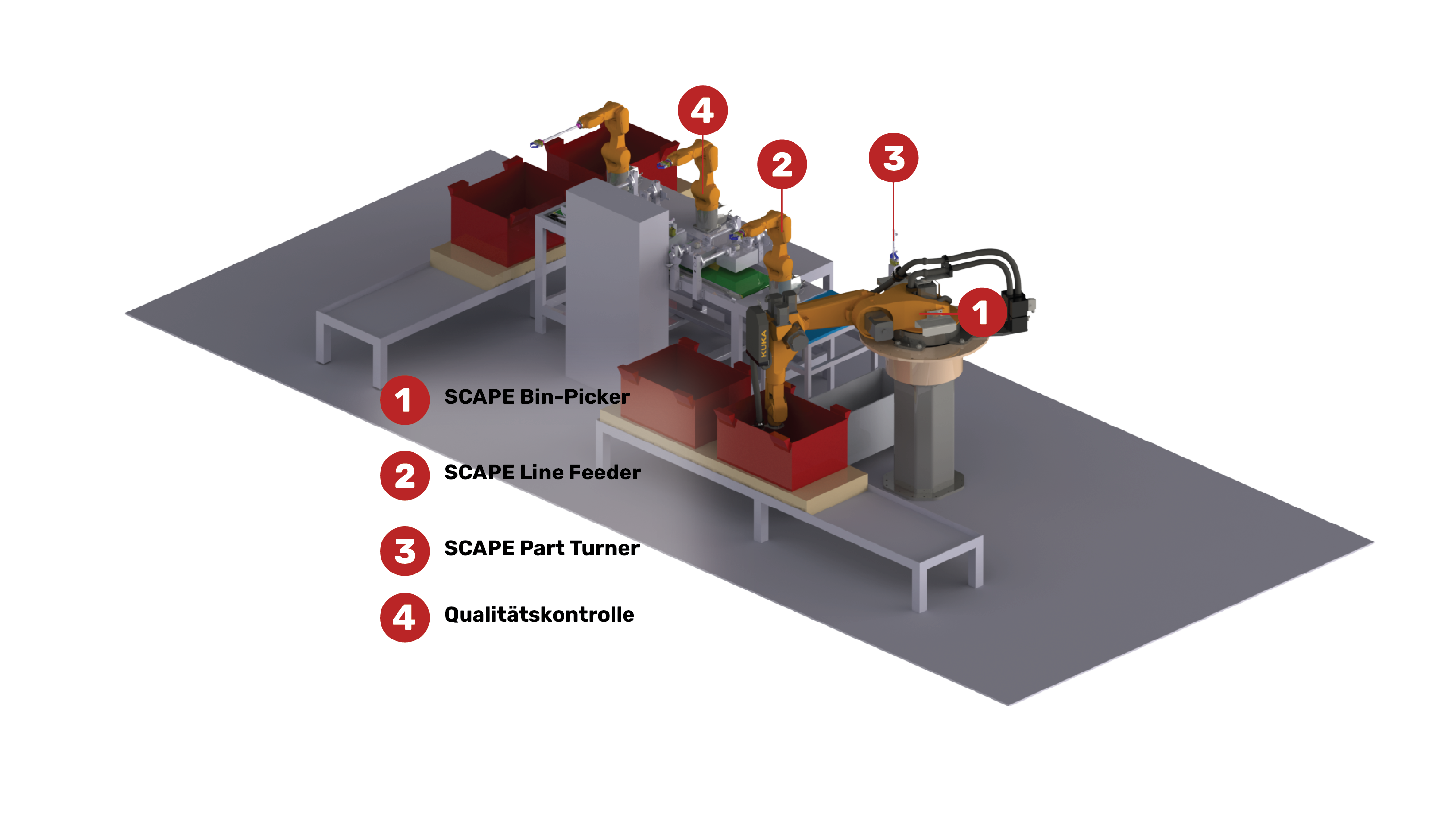

SCAPE BIN-PICKER SOLUTION

Bin-Picking Rails at HEYCO Tittling

See the system in action:

The SCAPE Bin-Picker and SCAPE Line Feeder Solutions take care of all the critical steps:

• Recognizing parts in the bin

• Selecting and picking parts from the bin

• Planning the optimal path for robot motion

• Ensuring part orientation for precision delivery

• 100% precision delivery of parts

A part is delivered into the next process average every 10-12 seconds.

The SCAPE Stationary Scanner recognizes the parts in the bin, from where the SCAPE Bin-Picker robot grips the and places them onto a SCAPE Handling Station table. From there, the SCAPE Line Feeder grips the parts precisely and delivers them onto the conveyor belt in the inspection machine in the correct orientation. If needed, the parts are turned on the way with the SCAPE Part Turner.

Cycle time:

10 - 12 seconds

Part weight and dimensions:

3 kg; 35 x 70 x 20 cm

Part delivery:

Precision delivery onto conveyor belt

Vision sensors:

One SCAPE Stationary Scanner above the bin and one SCAPE Stationary Camera above the table