Volkswagen Chooses Our SCAPE Bin-Picking Solution

December 12th, 2023

Customer: Volkswagen

Project Overview

Volkswagen faced challenges with their previous method of manually handling wheelhouses, each weighing about 8KG. The manual process was not only physically demanding but also impeded the integration of automation in upstream and downstream processes. To address this, the SCAPE Bin-Picking solution was integrated, aiming to revolutionize the loading and unloading of wheelhouses, enhancing efficiency and safety, and driving automation in the production line.

See the full case story here:

Problem Statement

The manual transfer of heavy wheelhouses at Volkswagen's production line was inefficient and physically demanding, obstructing the seamless automation of the production line.

Solution Deployed

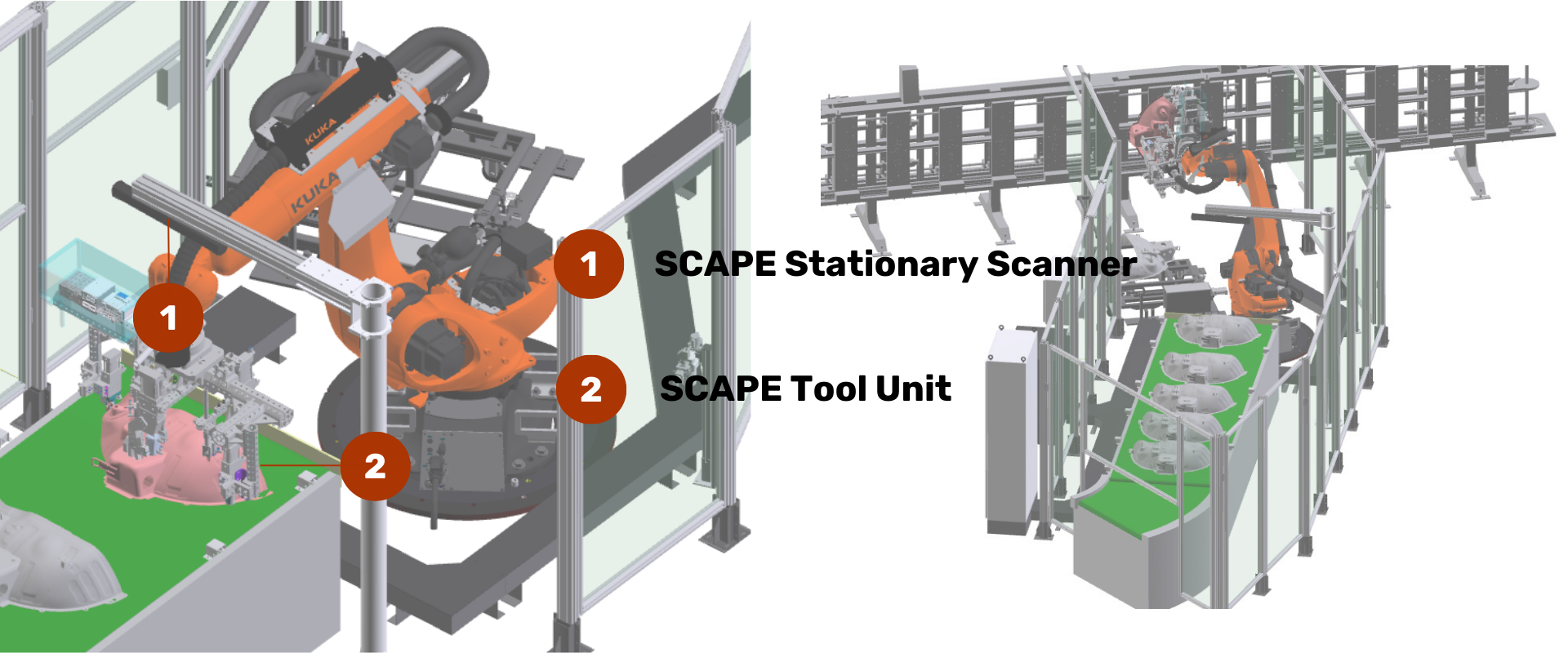

SCAPE Bin-Picking System: As the foundation of the solution, this system enables intelligent picking of disordered workpieces through advanced image processing, 3D recognition, and path planning algorithms.

High-Precision SCAPE 3D Vision Sensor: This sensor offers remarkable accuracy and flexibility, enabling precise identification and handling of wheelhouses.

SCAPE Tool Unit with Customized Gripper: Specifically designed to handle wheelhouses, this gripper facilitates precise placement onto downstream rotary equipment.

Turnover Material Car: This bespoke design addresses the issue of downstream process saturation. It efficiently transfers wheelhouses from the conveyor line to the turnover car, which can then be manually relocated.

Project Outcomes

Enhanced Efficiency: The integration of the SCAPE Bin-Picking solution has reduced the time per wheelhouses to an impressive 25 seconds, significantly boosting production line efficiency.

Labour Cost Reduction: The automated system has considerably decreased the reliance on manual labour, resulting in substantial cost savings.

Increased Operational Safety: By replacing manual handling with robotic automation, the risk of physical injuries to workers has been greatly minimized.

Automation of Production Line: The solution has successfully enabled the realisation of a fully automated production line for the handling of wheelhouses.

Conclusion

The implementation of SCAPE Bin-Picking solution for loading and unloading wheelhouses at Volkswagen has been a transformative step in the manufacturing process. It has not only enhanced efficiency and safety but also marked a significant move towards the automation of their production line, setting a benchmark for similar applications in the automotive industry.