Reliable Scape Bin-Picking Solution For Quality Inspection at Heyco Tittling

October 27th, 2022

THE SHORT STORY

The HEYCO company was founded in 1937. From 1980 onwards, the original production of hand tools expanded to include plastic parts and forgings, with HEYCO becoming a leading supplier for the automotive industry.

HEYCO is renowned for its consistent use of cutting-edge technology and its customer-oriented development in all corporate divisions. Expertise, innovation, and a high degree of flexibility are its recognized strengths. From early on, a standard of quality has been implemented on all company levels. HEYCO has its own in-house system for the implementation of continuous improvement processes and is certified according to the highest international standards.

At HEYCO-WERK SÜD in Tittling, Lower Bavaria - Germany, the reliable SCAPE Bin-Picking Solution is used in the quality inspection process of forged common rails.

THE CHALLENGE

At HEYCO-WERK SÜD in Tittling the common rails for automotive engines are produced.

A common rail injects highly pressurized fuel directly into the combustion chamber, which allows the fuel to burn more efficiently in a car engine. This leads to low fuel consumption, reduced emissions, and high-power output.

Forging is the best way to avoid common rail problems. When forged, the common rail is made of stainless steel and consists only of one piece which eliminates the risk of cracks and leakages.

Additionally, forging strengthens the material by closing empty spaces within the metal while deforming and shaping it with localized compressive forces.

After the forging, the common rail will go through several processes and undergo quality inspection to eliminate cracks and leaks in the common rails. Quality control requires monotonous handling tasks of the common rails, and it requires that the common rails are oriented in the same position and delivered precisely on a conveyor belt for inspection every 10 seconds. This is a job that can be handled by the flexible and reliable SCAPE Bin-Picker solution, which allows HEYCO to keep quality inspection running smoothly and achieve higher throughput and product quality. Automation is not about replacing humans; it is about freeing up workers to take on more responsibility and leave repetitive tasks to automation solutions.

THE SOLUTION

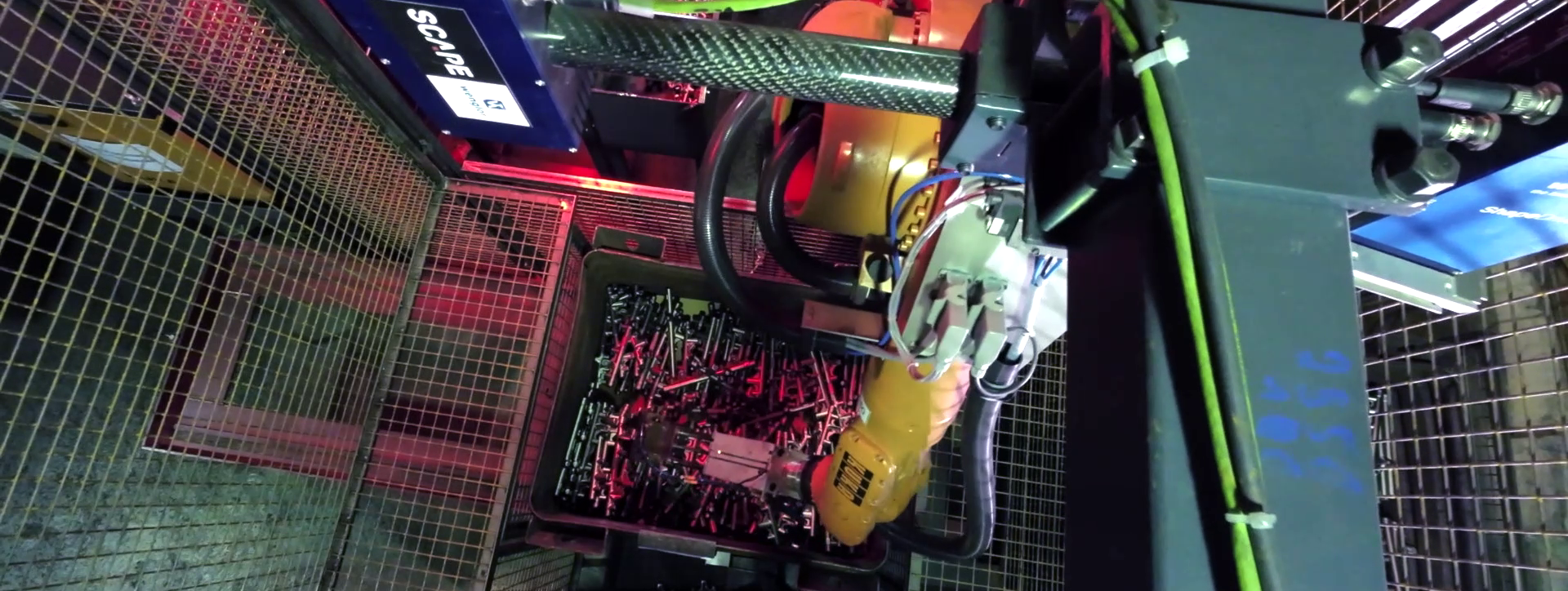

This handling process of common rails is carried out with the modular and reliable SCAPE Bin-Picker Solution. In this configuration 2 robots are used; one is Bin Picking Robot and the other is Line Feeder Robot. With this constellation, a cycle time of approximately 10-12 seconds can be achieved.

See the reliable SCAPE Bin-Picker Solution in action at HEYCO here:

The common rails are to be recognized from a container (1200 x 800 mm), gripped and placed on a conveyor belt in the correct position. The first robot is responsible for the bin-picking process from the container and the other robot grips the rails with precision from the handling station. After the components have been gripped in the container, they are placed on the handling station, above which a camera is mounted. The camera recognizes the position of the components and, if necessary, they are rotated by 180° in a part turning station. The common rails are then placed in the correct position on the conveyor belt for quality inspection.