NEW CASE: Slide Assembly Line for Car Seat Manufacturer

December 12th, 2022

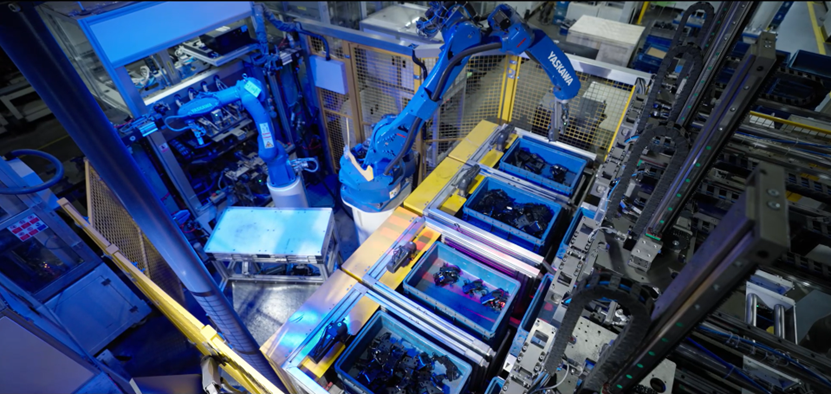

Our partner in China has implemented a SCAPE Bin-Picking System including Orientation Control for part precision delivery at a well-known automotive seat parts company.

In this system, Scape uses 6-axis robots from Yaskawa (GP25 and GP7) and SCAPE Stationary Scanners to handle four different sizes of randomly placed parts from bins for the loading process for the automated assembly line.

One of the robots is used for bin-picking from the KLTs, while the other handles part precision gripping, part turning if necessary, and part feeding to help the customer improve efficiency and save labour costs.

THE SOLUTION

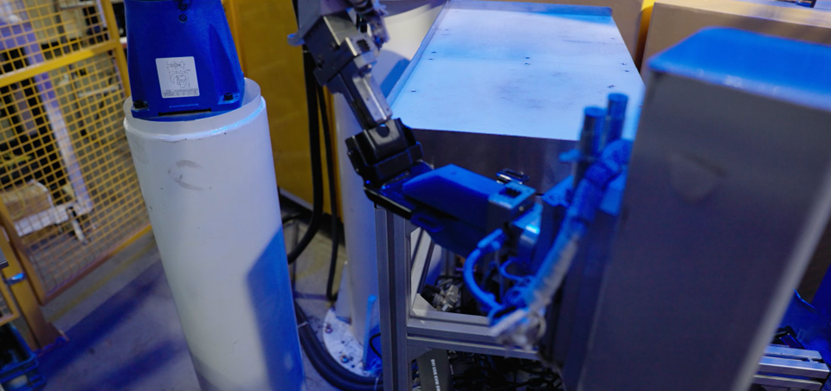

In this project, the equipment used by Scape includes SCAPE Bin-Picking Manager™, SCAPE Part Training Studio™, SCAPE Calibration Manager™, SCAPE Communication Server™, SCAPE Stationary Scanner E1 Recognition, SCAPE Part Turner, SCAPE Orientation Control and Scape Tool Units & Grippers.

The complete SCAPE Bin-Picker manage the gripping and delivery process within 10-30 seconds if some of the parts need to be turned before precision delivery. If all four parts need to be turned, the system can handle all part deliveries within 40 seconds.

See the SCAPE Bin-Picker Solution in action here: