What is a Pick and Place Robot? Types and Uses

April 28th, 2023

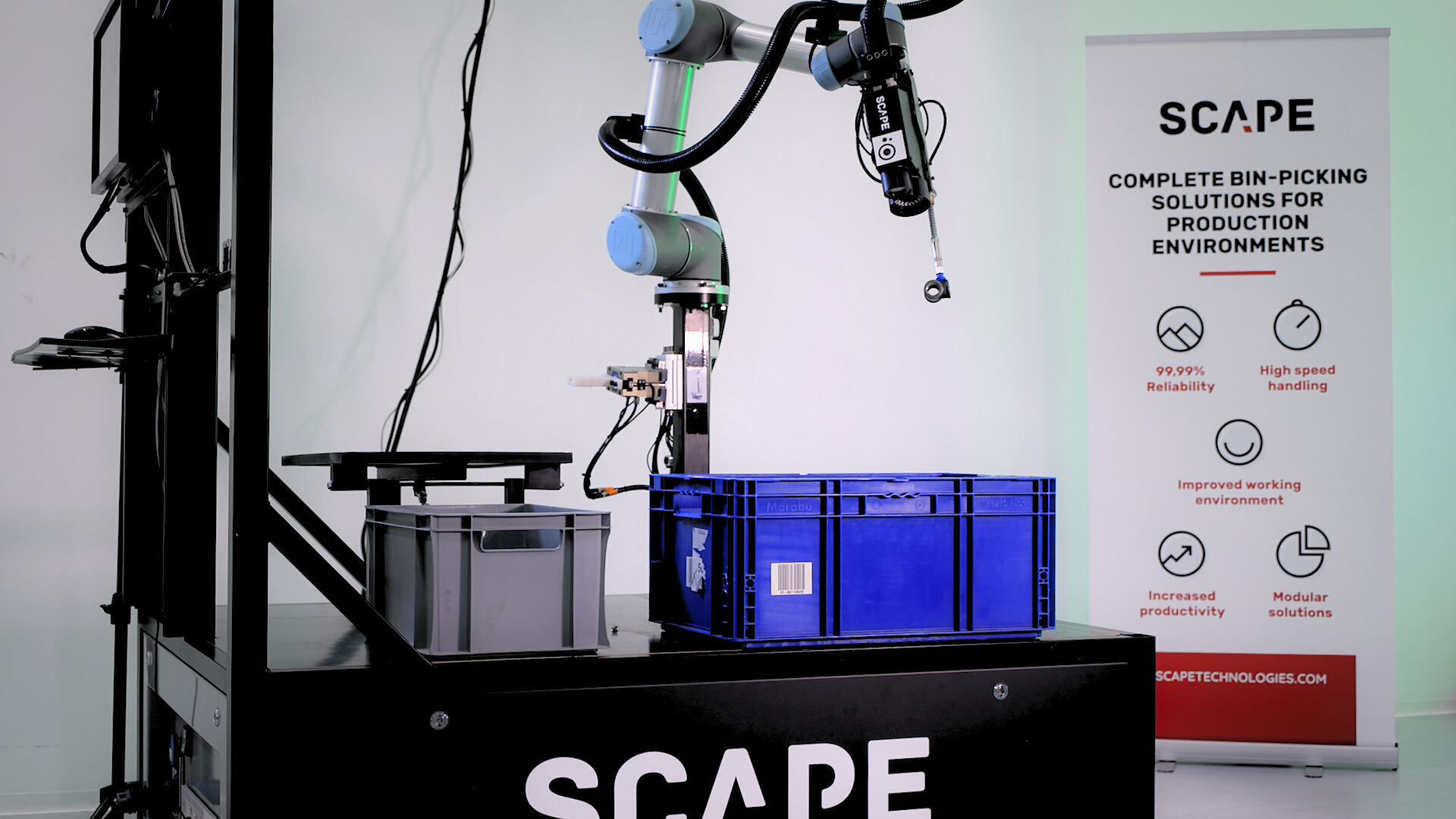

by Bogdan Tintescu, Marketing Assistant, Scape Technologies

What Is The Future Of Manufacturing?

At Scape Technologies, we focus on providing automation solutions in modern-day manufacturing. One such solution is the pick and place robot. In this article, we will explore the key features, benefits, and applications of pick and place robots, and how they can optimize manufacturing processes.

A pick and place robot is an automated machine that is designed to pick up and move objects from one location to another. It is equipped with a gripper tool that can grasp objects of various shapes, sizes, and weights, and move them with precision and accuracy. The robot is programmed to follow a specific path and perform a series of actions, such as picking, placing, sorting, or stacking, to complete a task, using advanced vision and artificial intelligence.

Pick and place robots come in various types, such as Cartesian, SCARA, Delta, and articulated robots. Our bin-picking solutions can be integrated on articulated robots, that can perform complex tasks with multiple degrees of freedom.

Benefits of Pick and Place Robots

By integrating pick and place robots into manufacturing processes several benefits can be expected:

Improved efficiency: Pick and place robots can perform tasks at a faster rate than manual labour, reducing cycle times and increasing throughput.

Avoid labour shortage: By integrating pick and place robots, the demanding and repetitive tasks can be automated, enabling workers to engage in more complex tasks that require human skills.

Flexibility: Pick and place robots can handle a wide range of objects, making them suitable for various applications and industries.

Integration: Pick and place robots can be integrated with other machines, such as conveyor belts, vision systems, and sensors, to create a fully automated manufacturing process.

Quality control: Pick and place robots can perform tasks with high precision and accuracy, ensuring consistent quality and reducing errors.

Increased safety: Pick and place robots can operate in hazardous environments, reducing the risk of workplace injuries and accidents.

Applications of Pick and Place Robots

Pick and place robots can be integrated in various industries, such as:

Sorting: Pick and place robots can be used to sort products based on their size, shape, colour, or weight, improving efficiency and reducing errors.

Packaging: Pick and place robots can be used to pack products into boxes or containers, improving efficiency and reducing labour costs.

Material handling: Pick and place robots can be used to move materials from one location to another, such as loading and unloading machines or transferring materials between conveyor belts.

Assembly: Pick and place robots can be used to assemble products, such as electronic components, automotive parts, or medical devices, with high precision and speed.

Conclusion

In conclusion, pick and place robots are an effective solution for optimizing manufacturing processes. They offer high accuracy, flexibility, speed, safety, and integration, while providing numerous benefits, such as improved efficiency, cost savings, quality control, and increased safety. With their various applications, pick and place robots can help automate manufacturing processes and improve overall productivity.