Robots vs Cobots: What are the differences?

January 10th, 2024

by Bogdan Tintescu, Marketing Assistant, Scape Technologies

Introduction

In today's fast-paced technological landscape, businesses are increasingly adopting automation solutions to streamline operations and boost productivity. Two popular choices for implementing automation are industrial robots and collaborative robots, commonly known as cobots. This comprehensive article explores the distinctions between these two solutions, enabling you to make an informed decision when selecting the ideal automation solution for your business.

Understanding Industrial Robots

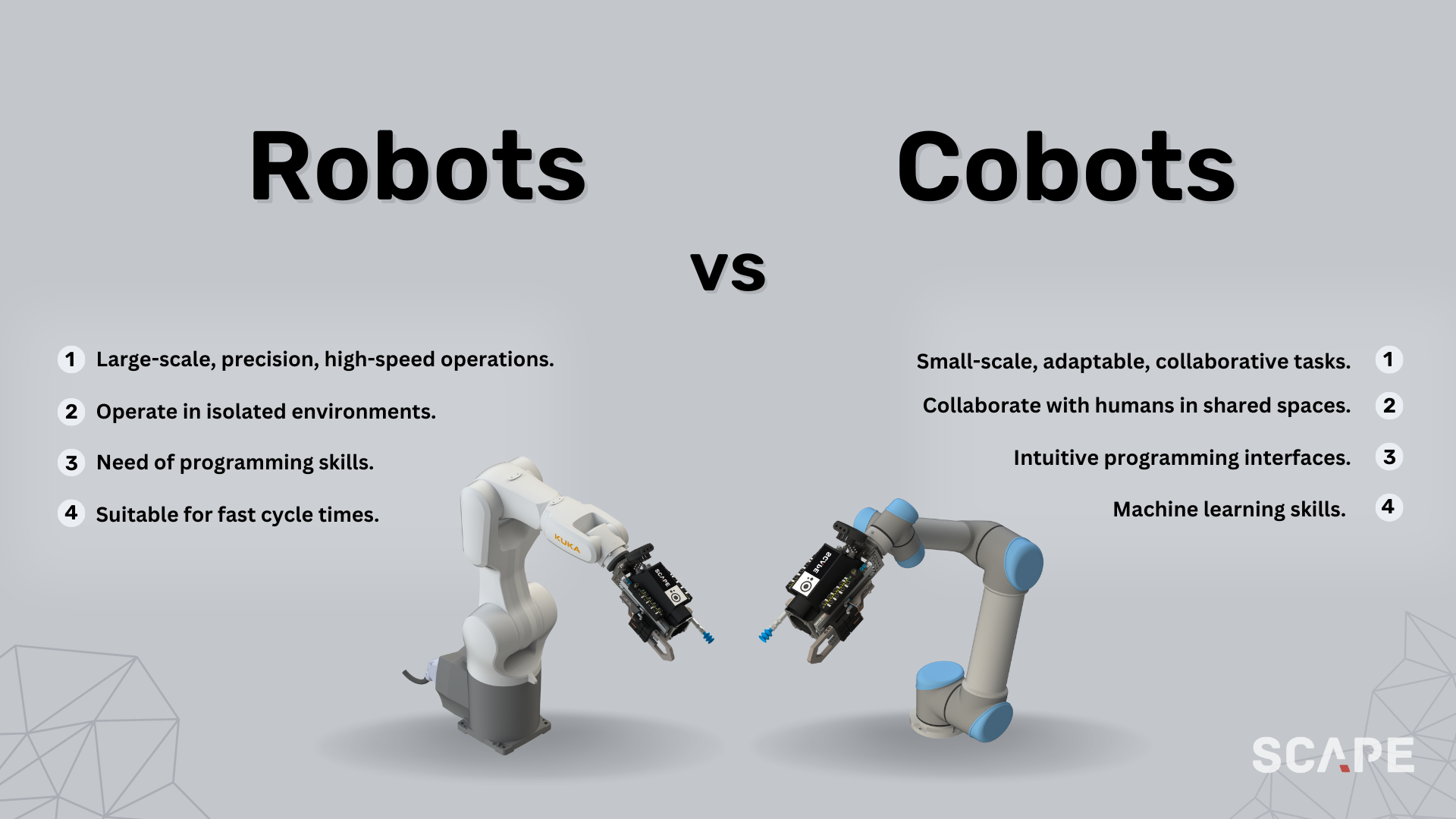

Industrial robots have served as pillars in manufacturing industries for several decades. They are specifically designed to perform repetitive tasks with precision, speed, and consistency. Typically utilized in large-scale manufacturing facilities and assembly lines, industrial robots excel in handling heavy loads and efficiently executing tasks requiring a high degree of accuracy.

Benefits of Industrial Robots

- Increased Productivity: Industrial robots operate tirelessly without breaks or fatigue, resulting in heightened productivity levels and improved throughput.

- Precision and Accuracy: These robots perform tasks with exceptional precision, reducing errors and enhancing overall output quality.

- Heavy Load Handling: Industrial robots are engineered to manage substantial loads, making them well-suited for lifting and moving heavy objects.

Exploring Collaborative Robots (Cobots)

In contrast, cobots are specifically designed to collaborate with human operators. Equipped with advanced sensors and safety features, cobots ensure safe interactions with humans. These robots are flexible, easily programmable, and adaptable to various tasks and environments.

Advantages of Cobots

- Safety: Cobots incorporate built-in safety features such as force sensors, collision detection, and speed reduction capabilities, creating a secure working environment for human operators.

- Ease of Use: Cobots are user-friendly and can be rapidly programmed by non-experts. Their intuitive interfaces simplify the process of teaching robots new tasks.

- Flexibility: Cobots possess high versatility and can be easily reconfigured to perform different tasks, making them ideal for small-batch production and frequent product changes.

Space Efficiency: Collaborative robots have a compact size, requiring less floor space compared to traditional industrial robots. This feature enables businesses to optimize their workspace.

1. Task Complexity

Consider the complexity of the tasks you intend to automate. Industrial robots excel in highly repetitive and precise tasks like welding, assembly, and material handling. On the other hand, cobots are better suited for adaptable tasks involving collaboration and frequent human interaction.

2. Workspace Requirements

Evaluate your workspace limitations. Industrial robots often necessitate large dedicated areas, safety fencing, and restricted access zones due to their size and potential hazards. Cobots, with their smaller footprint and advanced safety features, can operate alongside humans without the need for extensive safety measures.

3. Cost and Return on Investment (ROI)

Analyze the upfront investment, ongoing maintenance costs, and return on investment (ROI). Industrial robots typically entail higher initial costs, but they deliver substantial long-term benefits in high-volume production scenarios. Cobots offer a more cost-effective solution, particularly for small and medium-sized businesses or applications with varying production requirements.

4. Workforce Collaboration

Consider the level of collaboration required between the robot and your workforce. If your goal is to enhance human productivity rather than replace human workers, cobots provide an ideal solution. Their collaborative nature allows human operators to work alongside robots, leveraging the strengths of both.

The Scape Technologies' Mission

The choice between industrial robots and cobots depends on your specific business needs, task requirements, workspace limitations, and budget considerations. Industrial robots excel in high-volume, repetitive tasks, while cobots offer flexibility, safety, and collaborative capabilities.

Scape Technologies specialises in delivering user-friendly and cost-efficient solutions for automation. By carefully evaluating your unique circumstances and considering the advantages and disadvantages of each solution, we help you make an informed decision that aligns with your business goals. Whether you opt for industrial robots or cobots, automation can undoubtedly revolutionise your operations, improve efficiency, and position your business for future growth.

Make sure you follow our social media channels to stay updated on the latest happenings. (LinkedIn, Facebook, Instagram, Twitter)